What if a metal could offer the density of gold, the strength of steel, and still be converted into complex shapes? Pure tungsten, which is brittle and difficult to work with, in contrast, tungsten alloy is a material engineered to balance extreme physical properties with usability.

Tungsten heavy alloy plays critical roles in many demanding applications. This article is your comprehensive guide to understanding this incredible material, exploring its unique composition, properties, and the diverse industries in which it is used.

What is Tungsten Heavy Alloy

Tungsten heavy alloy is a composite material made primarily of tungsten mixed with metals, such as nickel and iron, or nickel and copper. It is known for its extremely high density, high strength, and good use. These properties make it suitable for applications requiring significant weight or radiation shielding.

Properties of Tungsten Material

The properties of tungsten heavy alloy are as follows:

- It has high density, making it perfect for applications where space is limited but weight is important.

- It has the best radiation shielding effect.

- Due to the presence of different metals, it has excellent tensile strength.

- It can withstand exposure to many chemicals and environments.

- It has low thermal conductivity.

Composition of Tungsten Alloys

Tungsten heavy alloy is made up of tungsten with a binder of nickel paired with either iron or copper. The following are the compositions of tungsten alloy:

Tungsten and Nickel: They are dense and are used in radiation and military applications.

Tungsten, Nickel, Iron: The most common type, containing tungsten, nickel, and iron. It is known for its high density and is used in applications like radiation shielding and balancing weights.

Tungsten, Nickel, Copper: This alloy contains tungsten, nickel, and copper. It has higher thermal conductivity and is often used for applications where heat dissipation is important, such as heat exchangers and electrical contacts.

Tungsten, Nickel, Cobalt: They are used in extremely hard and wear-resistant materials. It is used for cutting tools.

Tungsten, Nickel, Molybdenum: It includes molybdenum and is known for its excellent wear resistance. It is used to make bearings and seal rings.

Applications of Tungsten Heavy Alloys

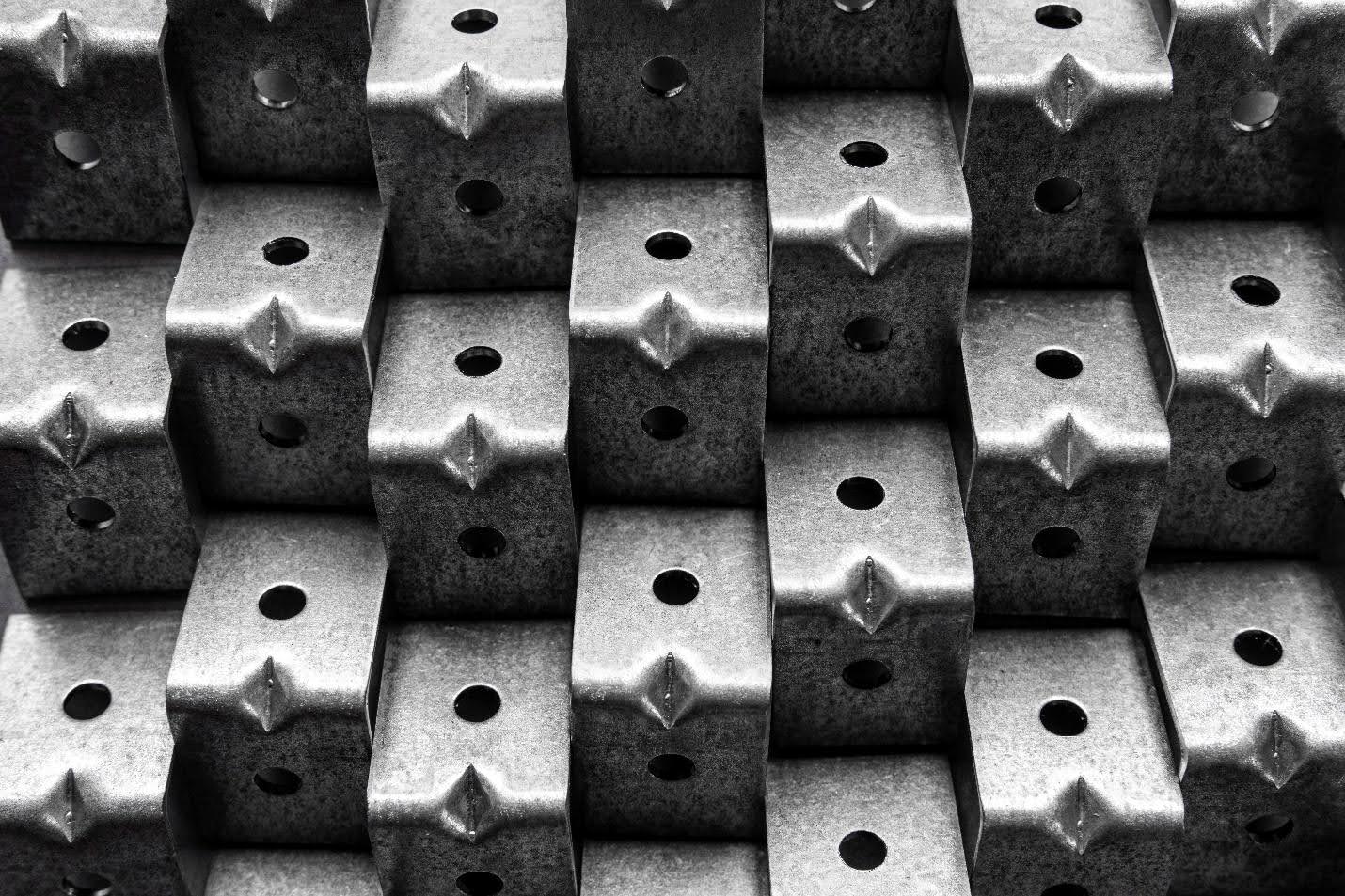

The added metals increase density, making it ideal for applications that require high density and weight. Tungsten heavy alloy parts are carefully placed into custom packaging foam inserts, protecting them from damage and ensuring safe transportation. These parts are used in important applications like industrial and aerospace.

1. Industrial Applications

Due to its high density, the tungsten can be small but still the same weight. It helps to keep the rivets in place. It is also used to build boring bars because it can absorb shock and vibrations.

2. Aerospace

It is used for balancing flight control surfaces, propellers, and other components to improve performance and stability. It is used in systems that require a large mass in a small volume, such as in steering systems.

3. Medical

The high density of tungsten alloy offers radiation shielding, making it an ideal choice in the medical industry. It is used to shape and direct X-ray beams in medical imaging equipment.

4. Military and Defense

It is used to create kinetic energy penetrators and other high-density components for military applications. Also, it is employed in missiles and other guidance systems to provide stability and accuracy.